Industrial machinery operates under immense stress, with equipment often exposed to fluctuating loads, misalignments, and unexpected surges in torque. These challenges can lead to costly downtime, component failure, and reduced productivity if not properly managed. The emergence of the a-series coupling that protects equipment in overload has redefined how engineers safeguard machinery against these risks. This advanced coupling technology ensures optimal performance, extends equipment lifespan, and provides a critical layer of protection against overload conditions that could otherwise damage vital mechanical systems.

Understanding the A-Series Coupling and Its Purpose

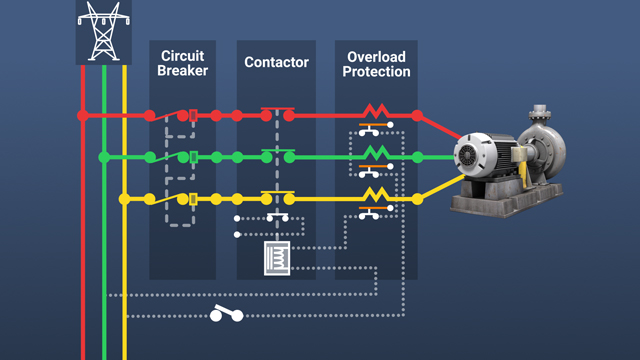

The a-series coupling that protects equipment in overload is designed with precision and innovation to handle high-torque environments while preventing catastrophic equipment damage. At its core, the coupling serves as a mechanical link between rotating shafts, transmitting torque while compensating for misalignments and isolating vibrations. Unlike standard couplings, the A-series design includes advanced overload protection features that disengage or slip when torque exceeds a preset threshold.

This intelligent safety mechanism allows the coupling to act as a mechanical fuse, instantly separating drive components from the load during overload situations. By doing so, it prevents excess stress from reaching critical parts of the machine, such as motors, gearboxes, and bearings. Once the overload is resolved, the system can be easily reset or re-engaged, depending on the coupling design, ensuring minimal interruption to operations.

The a-series coupling that protects equipment in overload is built from high-quality materials such as alloy steel, stainless steel, or composite compounds that enhance durability and resistance to wear. These materials allow the coupling to perform reliably under extreme conditions, from heavy manufacturing environments to precision automation systems.

Engineers value this coupling not only for its overload protection but also for its ability to maintain smooth, consistent torque transmission. By reducing torsional vibrations and accommodating minor shaft misalignments, it contributes to quieter operation, improved energy efficiency, and less mechanical wear over time.

How A-Series Coupling Protects Equipment in Overload

Overload events occur when machinery experiences torque beyond its designed capacity. These events can result from sudden starts, load jams, power surges, or operator error. Without proper protection, the excess torque can damage components, disrupt processes, and lead to costly repairs. The a-series coupling that protects equipment in overload acts as a safeguard against these conditions by instantly responding when torque exceeds safe limits.

The coupling’s internal mechanism, often featuring precision-engineered detent balls, springs, or shear pins, reacts to the excess load. Once the preset torque threshold is reached, the coupling disengages, effectively disconnecting the drive from the driven component. This immediate reaction prevents torque from transferring to sensitive parts of the system, reducing the risk of gear damage or motor burnout.

After disengagement, the system either automatically resets or requires manual re-engagement, depending on the model. This flexibility allows operators to select the most suitable configuration for their application, whether they prioritize automatic recovery or controlled restart.

The a-series coupling that protects equipment in overload also minimizes vibration and shock loads that can result from torque fluctuations. Its torsionally flexible elements absorb mechanical shocks, providing smoother operation even under irregular loading conditions. This capability makes the coupling ideal for industries where consistent performance and precision are essential, such as packaging, robotics, and material handling.

Another significant benefit of this coupling technology lies in its adaptability. The torque threshold can be customized based on the specific requirements of the application, ensuring precise protection for every type of machinery. Whether used in light-duty equipment or heavy industrial machines, the coupling’s versatility provides engineers with confidence in its performance.

In many applications, the a-series coupling that protects equipment in overload also contributes to operator safety. By preventing mechanical failure, it reduces the risk of flying debris or sudden equipment shutdowns that could endanger personnel. This safety feature aligns with modern industrial standards, promoting both efficiency and workplace protection.

Advantages of Using A-Series Coupling Technology

The advantages of the a-series coupling that protects equipment in overload extend far beyond mechanical safety. One of its most valued benefits is reliability. Because the coupling automatically responds to overload conditions, operators can trust that their machinery is continuously protected, even when unexpected events occur. This reliability translates into lower maintenance costs and improved operational uptime.

Another major advantage is its contribution to equipment longevity. By preventing torque overload from damaging gears, motors, and drive components, the coupling helps preserve the integrity of the entire power transmission system. Over time, this reduction in wear and tear leads to fewer part replacements and lower total ownership costs.

Energy efficiency also improves when using this coupling technology. Smooth torque transmission and reduced vibration result in more efficient power delivery, minimizing energy loss and improving machine performance. In high-volume production environments, even small gains in efficiency can translate into significant long-term savings.

The a-series coupling that protects equipment in overload is also easy to install and maintain. Most designs feature modular construction that simplifies alignment and replacement, allowing technicians to perform maintenance quickly without extensive downtime. This simplicity enhances overall productivity and ensures minimal disruption to ongoing operations.

From an engineering standpoint, the coupling provides flexibility across a wide range of applications. It can be configured to handle varying torque capacities, speeds, and environmental conditions. Whether used in conveyor systems, printing presses, compressors, or pumps, its adaptability ensures it meets the unique demands of different industries.

The Future of Overload Protection Technology

As industrial systems become more automated and data-driven, the demand for intelligent mechanical components continues to rise. The a-series coupling that protects equipment in overload represents a step toward smarter, safer, and more efficient machinery. Future advancements in coupling technology are expected to include integrated sensors and monitoring systems capable of detecting overloads, misalignments, and vibration levels in real time.

These smart couplings will allow maintenance teams to predict potential failures before they occur, transitioning from reactive maintenance to predictive maintenance. This evolution will significantly reduce downtime and operational costs while enhancing equipment reliability.

Material innovations will also play a key role in the continued advancement of the a-series coupling. Engineers are exploring advanced alloys and composite materials that provide higher strength, better heat resistance, and improved flexibility. These enhancements will enable couplings to perform reliably even in extreme industrial environments where both torque and temperature variations are intense.

Additionally, sustainability is shaping the design of modern industrial components. The a-series coupling that protects equipment in overload contributes to eco-friendly operations by extending the lifespan of machinery and reducing material waste. As industries strive to achieve greener production goals, durable and efficient mechanical systems will remain essential to that transformation.

The continuous innovation behind the a-series coupling reaffirms its value as a cornerstone of modern mechanical design. By combining overload protection, vibration control, and efficient torque transmission, it enhances both performance and safety. Engineers, operators, and manufacturers alike recognize it as an indispensable solution for protecting equipment, maintaining productivity, and optimizing long-term performance.

In the competitive world of industrial operations, every component plays a crucial role in maintaining efficiency and preventing costly downtime. The a-series coupling that protects equipment in overload exemplifies how engineering ingenuity can safeguard valuable assets while promoting operational excellence. As technology continues to evolve, this coupling will remain a vital part of the machinery that powers industries around the world, ensuring reliability and protection where it matters most.