Driveline load testing finds vulnerabilities before failure. Controlled driveshaft stress testing identifies hidden flaws. Technicians replicate driving loads with specialised equipment. Early detection prevents noise, vibration, and expensive component replacement. Load testing guarantees torque transfer under stress. Understanding the procedure ensures driveline safety and smooth rotation. Testing enhances vehicle handling and drivetrain longevity. Neglecting load testing can cause unexpected failures and harm.

Dynamometer Testing

Dynamometers measure torque, rotational speed, and driveline response accurately. Driveshaft are mounted and subjected to varying loads systematically. Sensors record stress, deflection, and vibration during operation carefully. Data identifies weak points, imbalance, or excessive flex in the shaft. Repeating tests under different conditions ensures thorough assessment of integrity. Dynamometer testing highlights hidden driveshaft weaknesses before failure occurs. Results guide repair or replacement decisions for safe operation.

Visual and Instrumented Inspection

Inspection during load testing combines visual checks with measurement instruments. Cameras or laser sensors monitor shaft movement and alignment precisely. Visual cues such as bending, cracking, or vibration are recorded continuously. Instruments detect minute deflection, imbalance, or rotational irregularities reliably. Comparing measurements against manufacturer specifications identifies critical deviations accurately. Combining visual and instrument data ensures precise diagnostics. Early detection allows targeted maintenance preventing extensive drivetrain damage effectively. For dependable driveline service, many drivers trust expert Auto Repair in Chesapeake, VA.

Vibration Analysis

Load testing evaluates vibration characteristics under torque and rotational stress. Accelerometers detect frequency, amplitude, and location of excessive movement carefully. Imbalance, worn joints, or damaged bearings often reveal vibration patterns. Technicians interpret data to isolate specific components causing instability. Corrective actions include balancing, joint replacement, or shaft realignment. Vibration analysis exposes underlying driveshaft issues before serious failure. Maintaining proper vibration control ensures smooth torque delivery and vehicle stability.

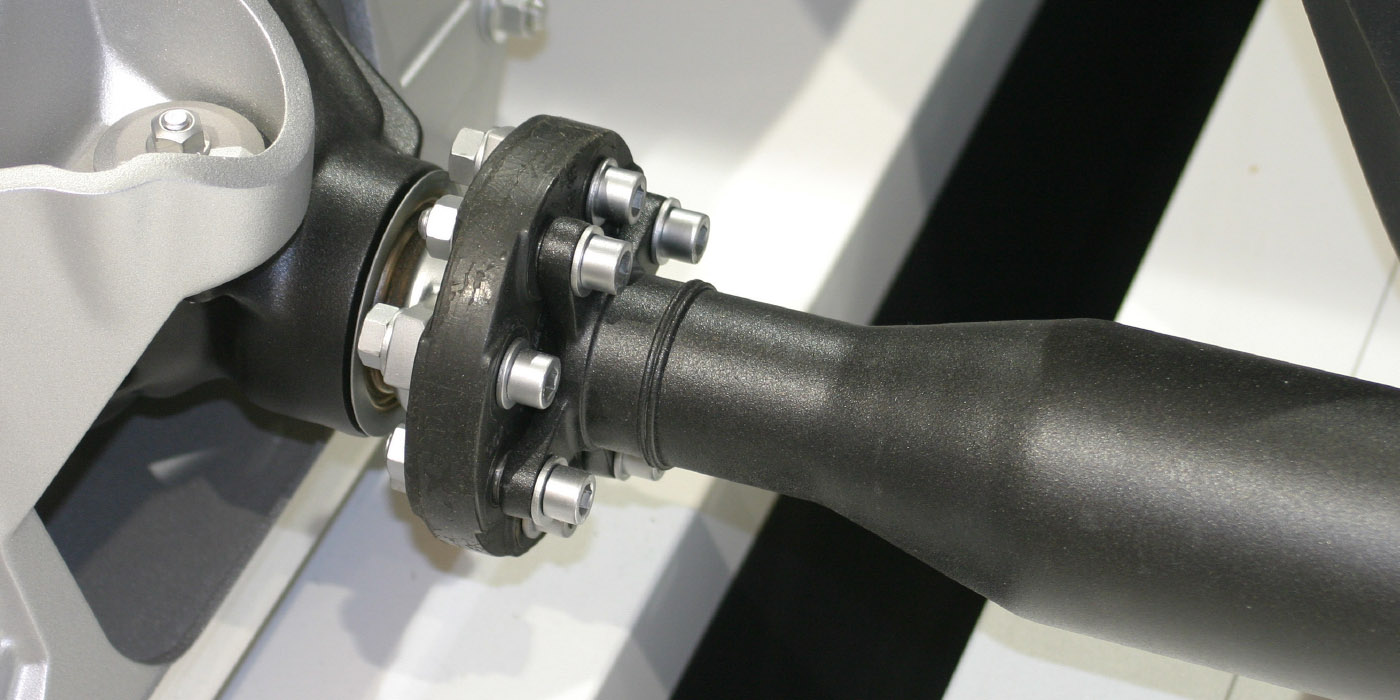

Joint and Bearing Assessment

U-joints, CV joints, and center bearings are stressed during load testing. Excessive play or binding under torque signals component weakness clearly. Technicians measure angular movement and rotational smoothness while monitoring response. Properly functioning joints maintain constant velocity and smooth rotation under load. Damaged or worn bearings increase stress on the shaft and joints. Assessing joints and bearings prevents driveline failure effectively. Timely repair maintains smooth torque transfer and reduces vibration reliably.

Post-Test Evaluation

After testing, technicians review data and visual observations carefully. Weak components are identified for repair or replacement immediately. Load testing confirms the effectiveness of corrective measures and adjustments. Documentation ensures future maintenance and prevents overlooked weaknesses in the driveline. Post-test evaluation validates driveline strength and integrity reliably. Regular testing improves vehicle safety, performance, and long-term component durability consistently.

Conclusion

Load testing reveals hidden driveshaft weaknesses under controlled stress conditions. Dynamometer tests, visual inspection, vibration analysis, and joint assessment are combined. Early detection prevents vibration, noise, and potential failure during operation. Corrective measures restore smooth torque transfer and driveline stability effectively. Post-test evaluation and documentation maintain long-term reliability and safety.